Basic maintenance checklist

The fixes for a garage door that makes a racket when it opens and closes are fairly easy and will take less than an hour. Start by tightening all the door and track hardware (Photo 1). Use a deep socket and a ratchet on all the nuts to snug them up. But don’t overtighten—that can pull the carriage bolt heads right through the door skin or strip the lag screw holes.

Next, check for worn rollers and hinges (Photo 2). Many track rollers have unsealed bearings that self-destruct after years of rolling around in a dirty environment. The wear can be so severe that the rollers actually wobble as the door operates. If your rollers are worn, consider replacing them with nylon rollers with sealed bearings (available at garage door suppliers or online). Nylon rollers are quieter and don’t require periodic oiling. But they are more expensive than steel.

Replace track rollers one at a time (Photo 2). If your door uses torsion springs mounted on the header above the door, do NOT attempt to replace the rollers in the bottom brackets. Those brackets are under constant spring tension and can cause serious injury if you unbolt them. That’s a job for a pro.

Worn hinges are less common than worn rollers. But sloppy hinges make a lot of noise and can cause the door to bind and wear out the tongue-and-groove joints at the door sections. Some play at the hinge is normal. But if you see an oblong hole where the tubular hinge pin mates with the hinge bracket, replace the hinge. Gray dust and metal filings around the hinge pin are early signs of wear.

Once you’ve replaced the worn door components, check the garage door opener chain. A loose garage door opener chain makes loud slapping sounds and causes jerky door movements that smack the rollers against the track. So start by tightening the chain (find the procedure in your owner’s manual). If you have a track drive opener, the next step is to lubricate the opener track with grease. If you have a screw drive opener, grease the threads (Photo 4).

Next, spray the hinges, roller bearings (unsealed style), and springs (Photo 5) with a garage door lube like the Prime Flo garage door lubrication kit (about $7 at home centers). Also hit the torsion bar bearings, and any other pivot points. The special garage door lube penetrates the parts as a liquid and dries to form a non-tacky grease that won’t attract dirt and dust, which can gum things up. Lubricate all moving parts every six months to reduce wear and keep the door quiet. Avoid other lubricants such as oil, grease, or spray lithium grease. They’re cheaper, but they don’t penetrate as well and tend to pick up dust and grit—just what you don’t want on moving parts.

Isolate the opener

If you have an attached or tuck-under garage and your opener seems loud inside the house, try this step.

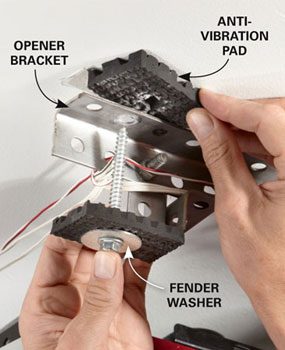

Mechanically isolate the opener from the garage rafters/trusses with rubber pads. Cut rubber pads out of an old tire, or buy specially made rubber/cork anti-vibration pads. (Four 5-1/2- x 5-1/2- x 3/8-in. pads are $14, available through our affiliation with amazon.com.) You’ll be adding about an inch in thickness, so you’ll need four longer lag screws and four fender washers.

Required Tools for this Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- 4-in-1 screwdriver

- Adjustable wrench

- Impact driver

- Socket/ratchet set

- Stepladder

- Wrench set

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list.

- Fender washers

- Garage door lube

- Lag screws

- Nylon rollers

- Replacement hinges

- Rubber anti-vibration pads

source: https://www.familyhandyman.com/doors/garage-door-repair/how-to-fix-a-noisy-garage-door/view-all/

If you need any garage door repairs or installation, contact A-1 Overhead Door

No comments:

Post a Comment